How to deal with plastic waste - activated carbon for waste treatment

Every year, the amount of plastic waste increases rapidly in the world, increasing the pollution of various environments and biological communities. Scientists have been looking for new ways to use and recycle plastics. Recently, a group of researchers have successfully used a variety of plastic waste to produce environmentally friendly jet fuel.

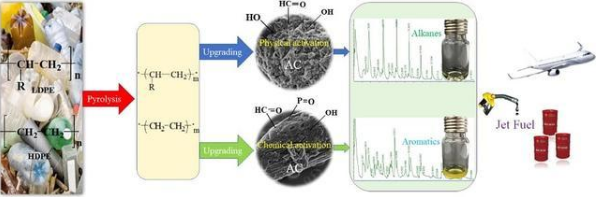

A team led by scientists at Washington State University has found a way to turn everyday plastic waste into jet fuel. In an article published in the journal applied energy, Han and his colleagues used activated carbon to melt high-temperature plastic waste and make fuel for airplanes.

"Plastic waste is a big problem in the world. It's a very good, relatively simple way to recycle these plastics, "Han said.

High temperature catalysis of activated carbon: the secret of plastic to fuel

During the experiment, Han and his colleagues tested low-density polyethylene and mixed various plastic wastes, such as water bottles, milk bottles and plastic bags, and then ground them into three millimeter particles - the size of a grain of rice.

Then put the plastic particles on the activated carbon in the high temperature tubular reactor, the temperature range is 430 ℃ - 571 ℃. Carbon is a catalyst, that is, a substance that accelerates a chemical reaction without being consumed by the reaction.

"Plastics are hard to break down and catalysts must be added to help break chemical bonds. Plastics contain a lot of hydrogen, which is an important component of fuel, "Han said.

Chemical process of plastic to fuel

Once the carbon catalyst has completed its work, it can be separated and reused for the next batch of plastic waste conversion. The catalyst can also be regenerated after losing its activity. After testing several catalysts at different temperatures, the best yield is a mixture of 85% jet fuel and 15% diesel fuel.

Environmental jet fuel

Before that, China refused to import foreign garbage, and domestic garbage in the United States, Japan, Malaysia and many other countries could not be treated. It is estimated that at least 4.8 million tons of plastic are thrown into the sea every year around the world.

This new process can not only reduce waste, but also use it more efficiently. "We can recycle almost 100% of our plastic materials. The fuel has very high energy and the gas produced is also environmentally friendly, "Han said.

This method is also easy to popularize. It can work in large facilities, even on farms, where farmers can turn plastic waste into diesel. "The resulting product must be separated to obtain jet fuel. If it's not done, then it's just diesel, "he concluded.