The role of activated carbon in organic synthesis

Activated carbon is one of the commonly used substances in organic synthesis experiments, which is mainly used to decolorize and remove impurities. According to the basic chemistry experiment book, the standard use method of activated carbon is to decolorize by heat filtration before recrystallization. In fact, there are other uses of activated carbon. It will bring a lot of convenience to organic synthesis experiment to make smart use of the properties of activated carbon and distinguish its advantages and disadvantages.

The functions of activated carbon in organic synthesis mainly include decolorization, adsorption and filtration aid. Generally, in the process of one operation of activated carbon, one aspect is mainly manifested, and the other aspects are secondary.

1. Decolorization

The most common function of activated carbon is decolorization. According to polarity analysis, activated carbon can be regarded as non-polar substances, which can be used to adsorb non-polar and small polar pigments, and is suitable for use in large polar solvents.

Most of the pigments contained in substances belong to non-polar or small polar pigments, so the most commonly used decolorizer is activated carbon, and the most commonly used solvents are water and alcohol.

Generally, when decolorization is needed, the polarity of pigment is not needed to be considered, and the decolorization effect can be judged directly by observing the change of solution before and after decolorization.

The general operation process is as follows:

The decolorized substance is added to a certain amount of solvent, heated to be fully dissolved, added to a certain amount of activated carbon, stirred for a period of time, heat filtered, and concentrated in the filtrate.

The substance to be decolorized is a solid or liquid containing visible pigment, most of which are solid;

The amount of solvent is generally 3-10 times, too little and difficult to operate, and the loss is large during hot filtration; too much cost is too high and unnecessary;

The solvents are generally large polar solvents, such as methanol, ethanol and water. If crystallization is needed after decolorization, the most suitable solvent should be selected;

The addition amount of activated carbon is generally 5-10% of the solute (i.e. the substance to be decolorized), which can be increased or decreased depending on the situation;

The mixing time generally ranges from 30 minutes to 2 hours, which can be increased or decreased depending on the situation;

The filtrate shall be treated according to the situation. If the appearance color changes little before and after decolorization, it can be decolorized repeatedly by adding active carbon; if recrystallization is needed, it can be cooled and crystallized directly or after proper concentration; if the substance to be decolorized is liquid, it is generally concentrated to dry.

2. impurity removal

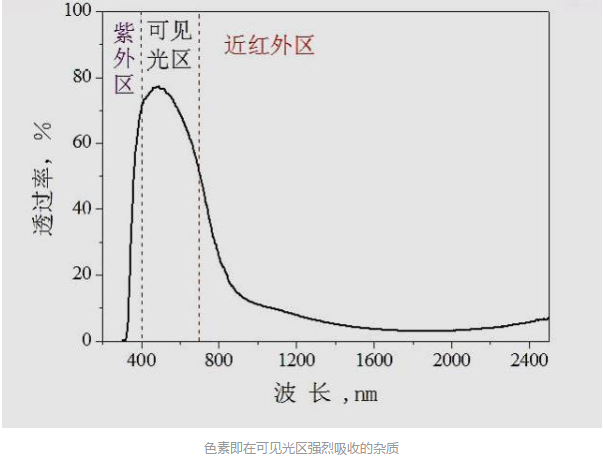

The impurities here mainly refer to insoluble substances, such as inorganic salts, dust and physical impurities, etc. in fact, the decolorization of activated carbon also belongs to the removal of impurities, but the removal of decolorization is organic visible light absorption impurities.

The process of impurity removal is very simple, similar to the decolorization process. After full dissolution, it is directly filtered and concentrated after stirring with activated carbon.

In fact, pure impurity removal can be achieved without adding active carbon, and direct full solution filtration can be achieved. Adding active carbon is mainly to make use of its role in facilitating filtration, which is beneficial to filtration.

3. adsorption

Adsorption is mainly aimed at tar and viscous impurities. If no activated carbon is added to this kind of substances, the filter medium will be blocked by direct filtration, and the general effect of activated carbon adsorption is obvious.

When the adsorption is mainly used, the activated carbon can be replaced by silica gel or diatomite with little difference.

Generally, in the process of using activated carbon, activated carbon has three functions of decolorization, impurity removal and adsorption. The colored impurities enter into the molecules of activated carbon, and the tar and viscous impurities exist between the particles of activated carbon. In the process of filtration, activated carbon helps to filter the insoluble impurities. The three functions cannot be separated.

In fact, the function of activated carbon in organic synthesis is very simple, but other problems often appear in the use of activated carbon. The most common problems are:

The decolorization effect of activated carbon is not good, and the color of filtrate is still heavy after decolorization for many times;

The loss of decolorization of activated carbon is more than 10%;

The product contains a small amount of activated carbon;

When adding activated carbon, the filtration is very slow, and the filter paper and filter cloth are blocked;

The reactor after the use of activated carbon is very difficult to wash, how to wash is not clean;

The poor decolorization effect of activated carbon is usually related to the polarity of the pigment, and the same decolorizer can not be applied to all the pigments; the loss of decolorization is generally due to the excessive adsorption of the product on the activated carbon; the main reason for the filtration cloth of activated carbon penetrating the filter paper is the incorrect selection of the activated carbon model; the blocking of the filter paper is related to the particle size of the insoluble matter as well as the model of the activated carbon The reactor is difficult to wash, which is related to the properties of activated carbon.