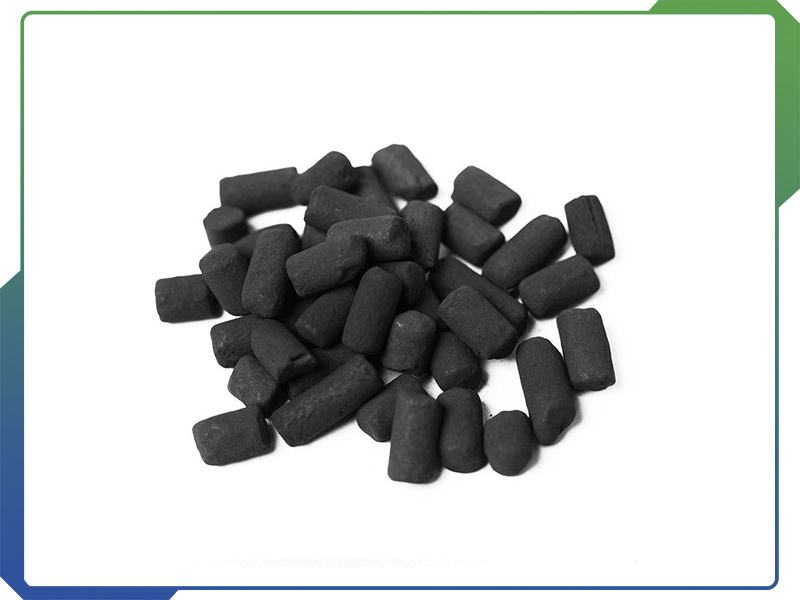

Active coke

Active coke is a kind of solid adsorbent used in chemical production, which is mainly used in dry desulfurization technology. The principle of active coke flue gas desulfurization is to make use of the adsorption characteristics and catalytic characteristics of active coke to make the SO2 react with water vapor and oxygen in the flue gas to form H2SO4 adsorb on the surface of active coke, heat and regenerate the SO2 active coke, release high concentration SO2 gas, recycle the regenerated active coke, high concentration gas can be processed into sulfuric acid, simple sulfur and other chemical products. 吸附原理2SO2+O2+2H2O=2H2SO4解吸原理2H2SO4+C =2SO2+CO2+2H2O;脱硝原理按适宜的氨氮比加入NH3,主要发生选择性催化还原反应生成N2和H2O,脱除NOx:4NO +4NH3+O2→4N2+6H2O ;2NO2+4NH3+O2→3N2+6H2O,产品广泛用于脱硫脱硝吸附塔和污水处理方面.

Advantages of using active coke:

Activated coke itself has nonpolarity, hydrophobicity, high chemical stability and thermal stability, can be activated and modified, coupled with its catalytic action, loading performance, reduction performance, as well as unique pore structure and surface chemistry, all determine that active coke has very good innate conditions in combined desulfurization and denitrification, and can achieve joint removal SO2、NO.XWith dust integration, SO2 removal ≥95%, NO.XThe removal rate ≥80% and the dust content ≤20 mg/m at the outlet of absorber3. ,

Specific product technical parameters are as follows:

Product model | Key technical indicators | |||||||||

Moisture % | Iodine adsorption values mg/g | kg/cm compressive strength2 | Wear resistance % | mg/g SO2 adsorption capacity | PH | Fire up ℃ | Ash ash % | Filling density Kg/m3 | Particle size | |

XHHXJ-90 | ≤5 | ≥400 | ≥40 | ≥98 | ≥40 | 7-10 | ≥400 | ≤15 | 600-700 | 5-9 mm Column optional |

XHHXJ-28 | ≤5 | ≥500 | ≥40 | ≥95 | ≥45 | 7-10 | ≥400 | ≤15 | 550-650 | 2-8 mm crushing optional |

[Appearance]: Black granular. [Standard]: If the inspection basis is in accordance with the national standard GB/T7702-1999, or the inspection method may be provided by the customer, the inspection shall be in accordance with its method.

[Packing]: The outer packing is made of PP plastic woven bag, and the inner bag is made of waterproof PE plastic inner film bag.

[Specification]: Product packaging specifications, according to customer requirements for packaging, the conventional use of 25 KG/ or 500 tons of bags KG/ packaging.

[Note]: Unlisted project quality indicators can be produced according to the specific needs of users.