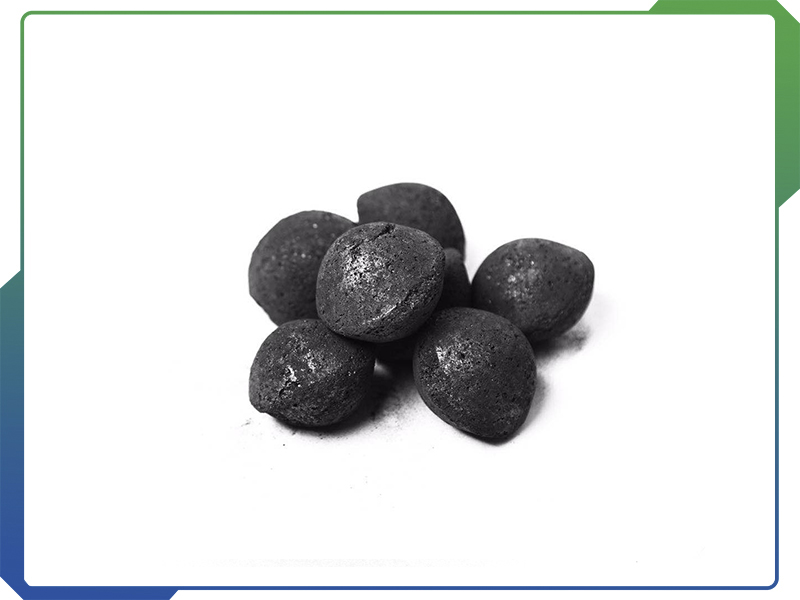

Iron-carbon microelectrolytic packing

After the packing arrives at the site, be sure to keep the packing dry and avoid flooding or moisture. Before the packing is added to the equipment, it is recommended to submit the detailed drawings of the equipment to us so as not to affect the use effect of the packing due to equipment problems. it is recommended to add 15-20 cm of cobblestone cushion on the bearing plate to prevent the packing from gradually consuming smaller after leaking from the bearing plate to the bottom and blocking the pipe, affecting the use. After the filler is added to the equipment, the filler should be soaked and covered with clear water or waste water immediately, so as to prevent the filler from being damp and causing the plate knot and adhesion, which will affect the use effect. facilities stop operation still to be covered with waste water immersion, do not expose to air, lest oxidation cause filler adhesion, resulting in plate knot (note: regular observation, so as not to waste water reflux or leakage, resulting in packing damage can not be used).

Specific product technical parameters are as follows:

Product model | Key technical indicators | |||||||||

Porosity | Fine iron powder | Physical strength | Wear resistance | Carbon content | Metal catalysts | Activator | Surface area | Share | Particle size (oval) | |

XHWT--23 | 65% | ≥75% | KG/CM2≥600 | ≥97 | ≥18% | ≥5% | ≥2% | 1.2 m2/g | ≥1.2/tonm3 | 2-3 cm |

[Appearance]: Black oval.

[Packing]: The outer packing is made of PP plastic woven bag, and the inner bag is made of waterproof PE plastic inner film bag.

[Specification]: Product packaging specifications, according to customer requirements for packaging, the conventional use of 50 KG/ bag or ton bag 1000 KG/ packaging.

[Note]: Unlisted project quality indicators can be produced according to the specific needs of users.